- Automotive Glass Line

- Architectural Glass Tempering

-

J Shape Glass Tempering

-

Flat Laminated Glass Line

- Spare Parts & Materials

HOT LINE 0086-15136360852

Add:No.99,Jinguyuan Road,Luoyang,China

Tel:0086-15136360852

Fax:0086-379-64723096

E-mail:info@m.teshizai.com

PC:471000

Reciprocating Bent Glass Tempering Furnace

Special Features:

1. Reciprocating type, multi working positions available.

2. Sectional heating, individual heating zones for each working position.

3. Ceramic plates at the top of oven

4. Ceramic rollers driven by triple belts ensure better simultaneous and stable running.

5. Using ceramic support for heating elements, which could avoid earth to avoid heater trouble

6. Gapless heating technology.

7. Sectional driving technology for motors

8. Network data for servo motor control mode to avoid disturbance.

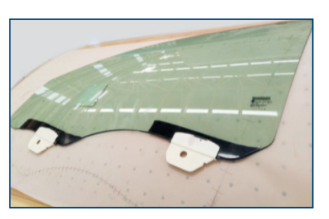

1. Machine Application

This machine is a special plant used to produce the bent

tempered glass, which mainly used in the fields of side doors (sidelites) of

automotives, trucks, shower room, furniture, etc. The side door of the

automotive should be single curvature. Our customer produced the side doors for

BMW, Audi, Toyota, Honda, Hyundai, Peugeot, etc.

2. Supply Scope:

2.1. Loading table

2.2. Heating section

2.3. Bent tempering & forming section

2.4. Unloading table

2.5.

Blower system

2.6. Electrical

& control system

2.7. Spare parts as listed in

appendix

2.8. Technical documents

3. Main Technical Features:

3.1. Loading Table:

3.1.1 Equipped with LED light to detect the glass with defects.

3.2. Heating Section:

3.2.1. There are ceramic plates at the top of oven, which could ensure more even heating, avoid dregs falling. But the cost is higher and has higher requirements on the installation.

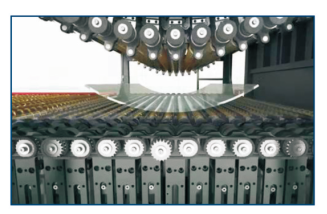

3.2.2. The ceramic rollers system is driven by triple belts, which can ensure better simultaneous and stable running, and avoid the scratch and destroy of glass when above the rollers. It would not affect the running when any one of belt damaged. The design as below picture:

3.2.3. Same top quality insulating materials for whole heating oven

3.2.4. Heating elements use the gapless design (parallelogram shape), which could make the heating more even. This could improve the finished product rate and better product quality. The design as below picture:

3.2.5. Using ceramic support for heating elements, which could avoid earth to avoid heater trouble

3.3. Control System

3.3.1. PLC, inverters. Contactors: Siemens

3.3.2. Network data for servo motor control mode: Profinet, compared with traditional wiring-connection, this mode could reduce dist

Model

Max.

Glass Size

Min.Glass Size

Thickness

Max.Depth

(mm)

(mm)

(mm)

(mm)

LV-TB1008

1000 x ⌒800

150 x ⌒200

3~6

≧400

LV-TB1209

1200 x ⌒900

150 x ⌒200

3.2~6

≧450

LV-TB1608

1600 x ⌒800

150 x ⌒250

3.2~6

≧400

LV-TB1810

1800 X ⌒1000

150 x ⌒250

3.2~6

≧500